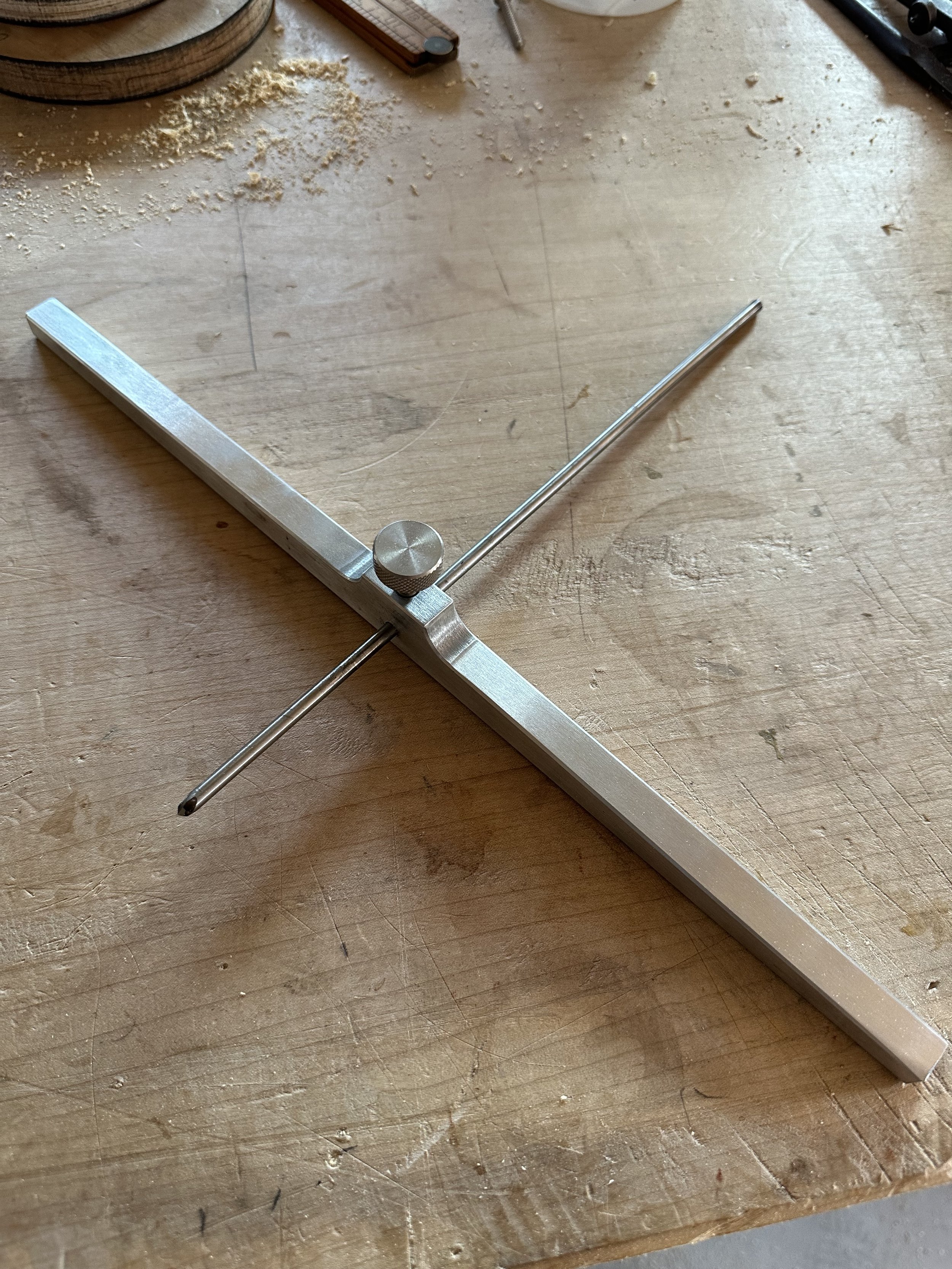

Wood Turner's Depth Gauge

For the past few years I’ve been developing a tool that I hope will help woodturners. It’s a depth gauge that drills a small hole into the bottom of a cup or bowl. The small hole acts as a visual aid to help get the depth right without constant checking with fingers or calipers. This saves a lot of time. And it’s simple to use.

I first learned of and used this tool when I studied wood turning in Japan in the spring of both 2018 and 2019. I was blown away at how simple and effective they were. And when I got back home I set out to make one.

In 2020 I asked my blacksmith friend Michael Jones if he could forge a few for me from mild steel. His versions worked great, but being made from iron, it sometimes stained the rims of the green wood I was turning. You may know the stains—it’s a purple or blue color that occurs from the wood's tannin rich sap oxidizing in contact with iron particles. It’s also known as ebonizing when done intentionally. Both Birch and Maple will show blotchy stains from my fingers or the tool itself. Usually both get small particles on them during sharpening. It’s annoying, but can be cleaned up. Once dry, Jazmin brushes on some lemon juice concentrate to the wood—poof the stains vanish. Pretty amazing.

I continued to use Michael’s gauges on the dry cups I was making, but I wanted something for green wood bowls too. Last winter I enrolled in a machine tool operation class at our local tech school. It was a night class and we met every week for a few months. The class was a sort of trial by fire affair. “What do you want to make?” said my instructor Wayne. I thought for a minute and explained the depth gauge to him. He then proceeded to guide me through the steps of machining one from a block of aluminum using a Bridgeport milling machine. That machine blew my mind. It can make anything. Seriously.

I tested the prototype on a few hundred bowls. Then sent some drawings of it over to Raney at Daed Tool works. Raney made up 10 prototypes and after a couple tweaks, another 10. I’m now ready to offer these tools up for sale. Raney will make the body and I will heat treat and grind the rods.

I’m not going to roll this out in a highly professional and organized way with branding, labels, etc…My wife and I run a very small business and time is…well there’s not enough time in the day—it’s that simple. Call it a soft start. I’m not even sure what to call it. I think Raney had it labeled Woodturner’s Depth Gauge on his drawings. Sounds good to me.

Here are the specs on my Woodturner’s Depth Gauge:14” aluminum body. Large 3/4 knurled grip thumb screw. 9” HSS drill rod. Simple and effective.

First, I’m going to sell the second set of samples. These are usable tools and the same as the final product save for the final finish—these will be just a little less polished. I’ve listed them on my webshop. Here They are reduced in price and go for $55. I’m also listing the main product for pre-order, which should ship late month. Price is $85. Here.

Here’s a little how to on its use.

When the bowl or cup is roughed turned for depth

Set the body of the gauge against the rim of the bowl or cup

Loosen the thumb screw and slide the drill rod to your intended depth. Shift your head so your eye is close to parallel to the base of the bowl or cup.

Tighten the thumb screw and while the lathe is spinning forward push the gauge and rod into the center of the bowl or cup. Limit the drilling to about 3/4”. If deeper it will drill slowly or clog. It also helps to have left a little dimple at the very center to help the rod find center.

Push the gauge into the wood until the main body hits the rim of the bowl or cup.

Now you have a small hole that you can turn to when completing the hollowing.

Turn the bowl or cups inside until the small hole is gone.